Introduction

When we talk about “digital dentistry” and digital solutions, there are many different aspects to “digitising” the modern dental office and our approach to treating our patients with a comprehensive range of digital devices:

- Dental computing software for charting and intraoral photography

- Extraoral photography

- Shade-taking devices

- Face scanners

- Intraoral scanners

- Cone beam computed tomography with low dose radiation

- Design and processing software – such as computer aided design/computer assisted manufacturing, implant planning software, prosthetic design software and digital smile design

- Chairside milling units

- In-office printing

- Laboratory-based milling and printing solutions

In my experience, though, the introduction and development of intraoral scanners has been by far the most significant clinical advancement.

I first began using intraoral scanners in 2002 with the old powdered CEREC system for chairside direct ceramic milled restorations. This powdered system was fundamentally flawed for absolute accuracy due to difficulties with moisture control (and powder contamination) amongst other things, but over time the systems have improved exponentially, and I would now argue that certain digital intraoral scanners have become the new gold standard for impression taking.

However, as we know there are always learning curves with any new technique and operator experience can make a significant difference to the clinical outcome.

Why the need for intraoral scanners?

Currently for crown and bridge procedures numerous conventional “wet” and digital impression techniques exist with varying degrees of accuracy and technique sensitivity. In 2005, Christensen observed the failures and limitations of conventional impression techniques from those received by dental laboratories, study clubs and postgraduate education programs.

The common problems with prosthodontic impressions were described as:

- Indistinct margin reproduction

- Incomplete margin representation

- Voids in the impression of the tooth preparation

- Voids or bubbles on the occlusal surface of adjacent teeth

- Cords impregnated in the impression

- Debris in the impression

- Impression material separating from the tray

This list is not exhaustive and is very dependent upon clinician experience for its success. In 2013, Gallucci and Lee clearly demonstrated that greater clinician experience improves the proficiency of the outcome when using conventional impression techniques, but clinical experience was less important for a proficient digital impression (see also German Gallucci’s congress lecture on the digital workflow available in the ITI Academy).

This shows that less experienced clinicians can decrease the learning curve and improve their clinical performance by using digital intraoral scanning techniques.

When you take a conventional wet impression there are so many different steps to make a “great” impression, whereas with an intraoral scan there is a relative known inaccuracy or tolerance with the equipment. When we take a conventional wet impression, we never truly know its accuracy until the restoration is made.

With an intraoral scan we have real-time feedback, quite often from the software, which will show any missing data and inaccuracies. It makes the whole process much more predictable, greatly reducing the need for laboratory remakes – in fact it’s incredibly rare now to have to send any type of lab work back for remake in my practices.

For patient-centered outcomes, digital impressions were found to be:

- More efficient requiring less clinical time

- Preferred by patients

- More comfortable

With increased numbers of commercial laboratories adopting a CAD/CAM milling workflow to streamline production and the move away from investing materials with the lost wax technique for crown and bridge unit fabrication, it is clear to see digital workflows are increasing in routine dentistry.

I have also found that my less experienced members of the clinical team are just as adept at taking digital intraoral scans as the more experienced members. The same cannot be said of conventional impressions, where operator skill and experience are essential.

Other factors that make digital impression techniques preferable to conventional techniques:

- Reduction of waste and mess

- Shipping costs to laboratories reduced

- No need for impression disinfection and therefore no risk of disease transmission to laboratory

- No need to pour models, trim and section dies with the relative inaccuracy associated with this – printed or milled models and their die fabrication are superior, allowing more predictability for restorations

- Assuming digital impression and occlusion are recorded accurately no need to articulate casts in appropriate cases

We also no longer have no issues with impressions being lost in the post, and the monthly cost of our digital scanner was easily saved in the reduction of postage costs alone. The speed of data transfer wirelessly also means that the laboratory has received the digital scan before our patient has even left the surgery.

Other cost savings include a massive reduction in dental materials costs, not just for the impression material but also the impression trays, disinfection materials, packaging for the post and reduced surgery time – because certainly intraoral scanning is much quicker so less time taken in the chair definitely increases surgery productivity and hours booked.

Patients also find the use of technology impressive and it can definitely raise your practice profile amongst competitors whilst also improving your predictability and increasing your clinical performance.

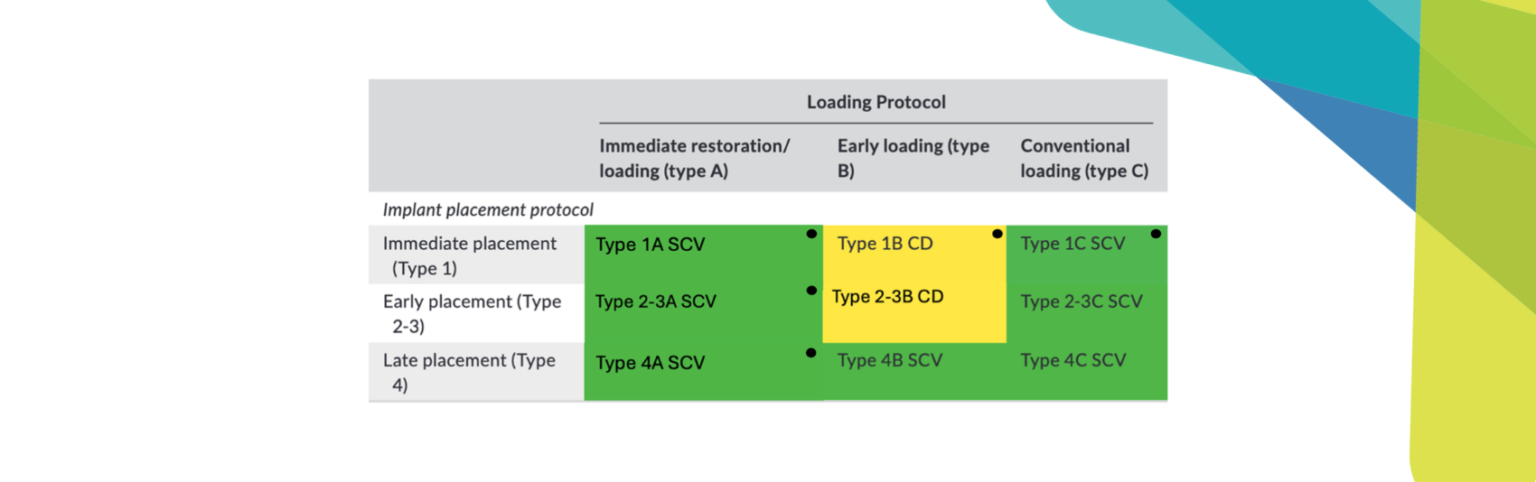

Consensus Statement on Impression Techniques

In 2018, the 6th ITI Consensus Conference in Amsterdam – where ITI Fellows and Members at the leading edge reviewed the scientific literature available for clinical best practice – formulated a series of clinical recommendations.

1. Accuracy of digital impressions with intraoral scanners of single or adjacent implants in partially dentate jaws and multiple implants in edentulous jaws is comparable to the accuracy of conventional implant impressions under laboratory conditions – based upon 6 bench studies

2. The accuracy of digital impressions is negatively influenced with an increase in the interimplant span between multiple implants in partially dentate and edentulous situations – based upon 3 bench studies

3. The scan protocol using intraoral scanners has a significant influence on digital implant impression accuracy in the edentulous jaw – based upon 4 bench studies using the same control

4. The accuracy of digital implant impressions of edentulous jaws varies when using different intraoral scanners – based upon 4 bench studies

Summary of Consensus Statement:

- The use of digital impressions for single implant restorations can be recommended

- To optimize digital implant impressions for each clinical situation, device-specific intraoral scanning protocols must be followed

- The use of scan bodies is recommended for accurate digital implant impressions

- Digital impressions of large inter-implant spans are not yet recommended for routine clinical use

- For routine clinical use, intraoral digital implant impressions of edentulous jaws cannot yet be recommended

Powdered versus non-powdered scanning systems

Some intraoral scanning systems require a surface coating to be applied to teeth in order for the intraoral scanner to precisely pick up topographical data. This is fine for benchtop scanning systems, but the oral environment is moist (as we know from our difficulties with placing composite restorations) and with such variations in patients’ anatomy in terms of cheeks and tongue size, and other factors such as saliva flow rate (some patients produce more saliva than others) that make “powdered” systems for me fundamentally flawed. Occasionally, I use a small amount of powder to cover a shiny metal surface of either a crown or a filling to permit the scanner a better optical image.

From 2002 to 2009 I used the powdered CEREC system and it was very difficult to have a truly reproducible scan (see below) – something which of course we expect from a digital system.

- Saliva contamination

- Crevicular fluid contamination

- Interference from cheeks and tongue

- Blood contamination from gingival trauma

- Sub-gingival preparations

These are all factors that contribute to a clumpy and uneven powder distribution which works against the nature of a predictable scanning system.

If moisture contamination does occur, then the area of interest can be dried, and the scanning powder reapplied but does this increase the thickness and change the accuracy of the scan data? It might, so it would seem logical to me to choose a system that doesn’t require such a technique-sensitive step.

My digital clinical workflows

So why do I use intraoral scanners? Because they add precision and predictability.

My digital impressions are used for:

- study model fabrication

- diagnostic wax-up fabrication

- fabrication of a surgical stent, synchronized in planning software with a CT scan

- provisional restoration fabrication

- definitive prosthetic restorations

- definitive denture fabrication

- longitudinal observation for tooth wear monitoring

- for orthodontic treatment planning

However, I can and do occasionally use wet impressions but for specific situations where I need fine margin detail, such as with veneer preparations or capturing an emergence profile in high esthetic demand cases (although I have even adapted my digital protocols to capture emergence profiles now).

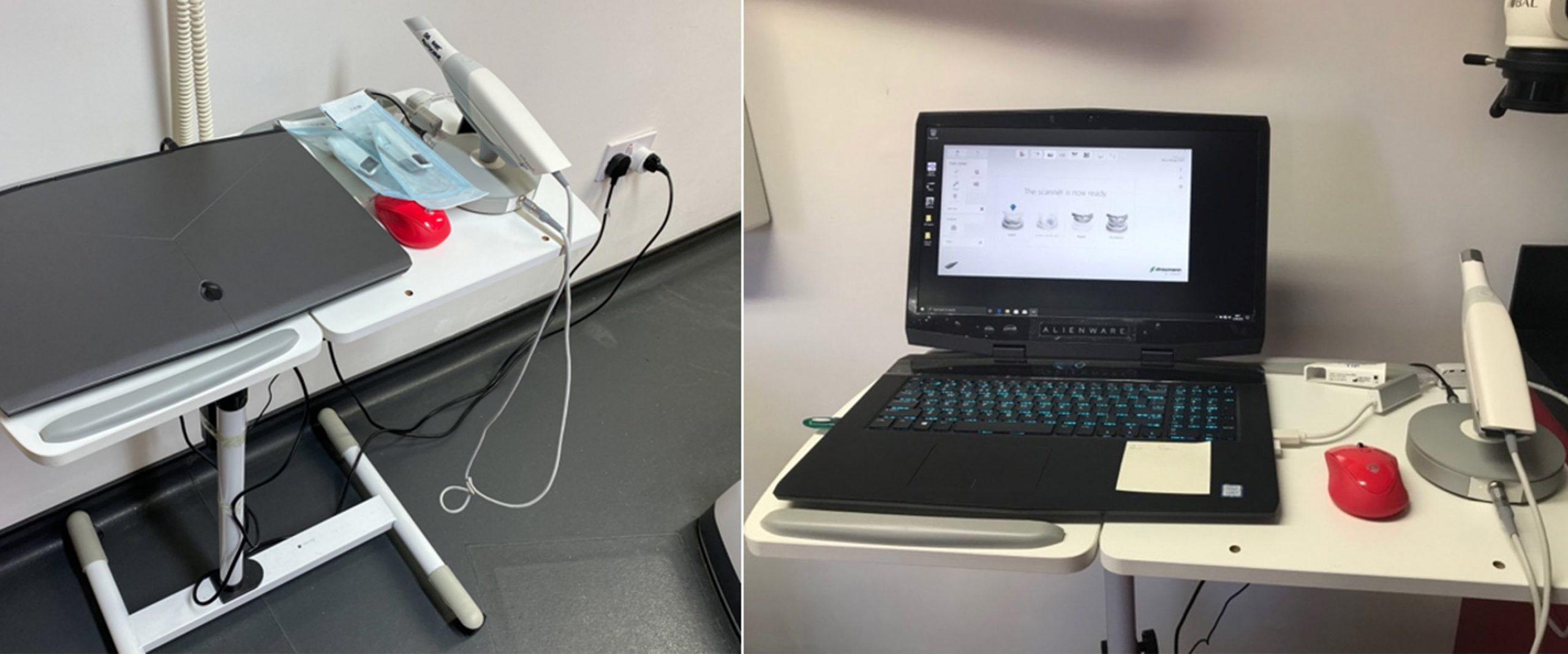

Over the years I have invested in different intraoral scanners and each one with increasing accuracy, reliability but, most importantly, ease of use.

Currently, the most frequently used scanner in my practices is our Trios from 3Shape. Of the different scanners used, each one has a different technique sensitivity.

The old iTero scanner (powder free) – from circa 2012 – produced very accurate scan data, but the scanner head was quite big and bulky, and the scanner operated by taking a series of images and stitching them together.

The CEREC Omnicam (powder free) we use is primarily for chairside ceramic restorations and is extremely reliable as a scanner for its primary function. However, it is a very closed system – i.e. doesn’t talk to other software systems – and this means utilising it for other applications is very limited.

The Dental Wings scanner (initially powdered but became powder-free with later versions) I have used with Straumann implants, and have tried a couple of variations to it. The intraoral scanner had a very ergonomic design and was wand like – however it was very technique sensitive and used a very specific focal depth – this makes implant scanning often difficult because dental implant fixtures and their scanbodies can be deep in relation to their adjacent teeth. Whilst its accuracy was excellent, it was very technique sensitive and my less experienced clinicians became frustrated with it. It was also the first of the scanners to become truly open where we could easily export the digital scan data into other software packages.

However, the best by far has been the latest Trios scanners from 3Shape (powder free). Reliability, reproducibility and ease of use are fantastic. Its openness makes it amenable to so many different applications and, with ever improving software updates, it is still actively developing. I am trying to stretch the envelope with the scanner – such as mucostatic impression techniques for removable prosthetics – and it keeps impressing me with the accuracy of the scan data. Bravo!

As part of the scanning sequence we are even able to take a preoperative scan of the tooth/ teeth/provisional which allows us to copy the pre-existing occlusal scheme with much greater accuracy.

Many salespeople talk of increased profitability, speed of use and improved patient tolerance. However, for me the greatest benefits are the real time evaluation of the prepared tooth or implant scan.

- I can evaluate the quality of the digital impression immediately with the patient in the chair – if it appears inaccurate in any way, I can simply delete data and rescan to improve the image quality (wet impression inaccuracies will only be detected after 4-5 days once the model has been poured or at worst when fitting the final restoration).

- When the tooth you have prepared and scanned is blown up on a computer screen it is very easy to evaluate the quality of your preparation. It is very underreported how digital impression scanning can be a quality assurance tool – particularly for less experienced clinicians – it’s very easy to review the quality of your preparations and then improve on them by evaluating a digital image on a 15-inch screen rather than trying to evaluate a tooth preparation on a stone model die.

- Digital scans can also be reproduced an infinite number of times – helpful.

Although digital scans are more predictable and appear as accurate as wet impression techniques for complex rehabilitations, it is important, however, to remember the Consensus Statements and we should follow the usual stages such as the use of verification jigs to ensure passivity of fit of frameworks.

3Shape workflow for a routine implant case

Conclusions

Hopefully my enthusiasm for digital impression-taking using intraoral scanners has come through and they are becoming so versatile now in many different aspects of dentistry.

I have tried to give a brief outline of how they have changed my daily practice and certainly helped to improve my clinical predictability and outcomes.

It is incredibly rare now that I ever have to send a piece of laboratory work back due to a poor fit, and my chairside time for minor fitting adjustments of restorative work is minimal. We have worked hard as a team – myself, my clinical team and the laboratories I work in partnership with – to tailor our parameters for study model and working model fabrication, but also for tightness of contact points and occlusal clearance tolerances. Who would have thought this could be achieved through the addition of an intraoral scanner?

Finally, the in-house technology doesn’t have to stop there – it’s amazing how an intraoral scanner can begin a digital journey – printers and milling units allow rapid turnaround solutions that can benefit both patient and clinical team alike – especially in hours of need.